Exclusive: China Dominates The Solar Silver Supply-Chain

They are not messing around

Given Janet Yellen's China trip and concerns about Their Solar industry dominance and a recent report by BOA describing said dominance. We thought it appropriate to breakdown Silver's Supply Chain contribution to the Solar Value chain , as possibly the single most important component in Solar. Enjoy

Report Sections:

- Purpose

- China’s Solar Silver Supply-Chain

- What is the Silver Value-Chain?

- Value-Chain (Sweet Spot) Analysis

- What Else the Value Chain Says

- SOLAR CELLS> SOLAR PANELS

- PASTE>

- POWDER>

- Bottom Line: China Not Likely an Exporter

- Addendum: Not Enough Supply, Too Much Demand

1- Purpose

Having gotten somewhat of a handle on Silver supply, the purpose of this piece is to break down China’s Solar Supply-Chain to better understand where demand trends. In doing so we will also answer a question surrounding trends in China’s import/export matrix. Part 1 was entitled Not All Silver is the Same.

2- China’s Solar Silver Supply Chain

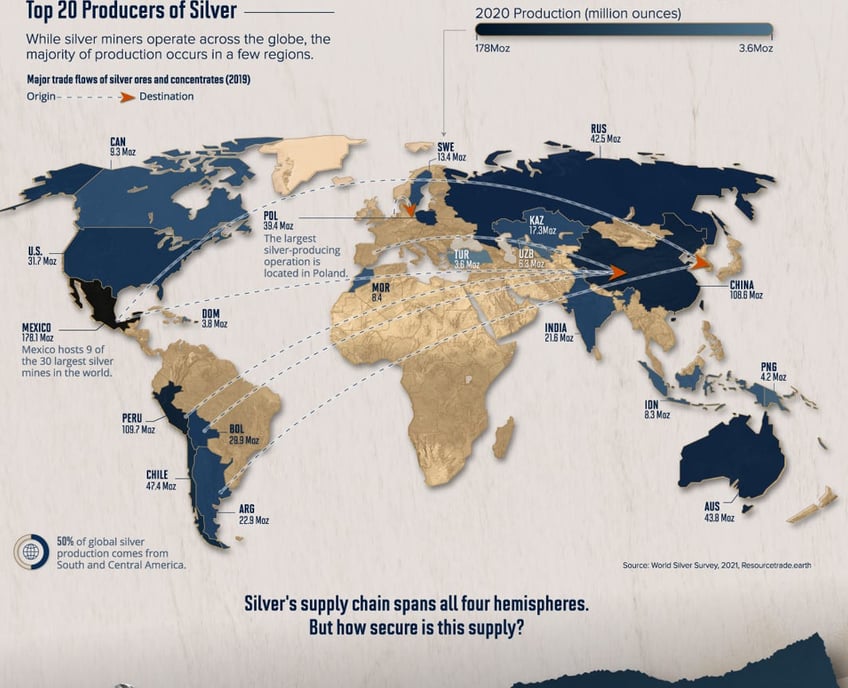

Silver is pulled out of the ground. It gets refined. It gets put into solar panels. The panels get installed. This is the supply chain.

Greatly Simplified, this is China’s Photovoltaic Silver Supply-Chain:

Mining>Refining>Solar Panel Creation> Panel installation

In our previous piece we discussed the mining portion of the Supply-Chain above. That helped us understand industrial supply issues. To summarize it here: based on proven reserves at current consumption rates due to net-zero energy applications, Silver will be in short supply in as little as 5 years.

In terms of Supply-chain analysis , that covers the “Mining” section in the above flow.

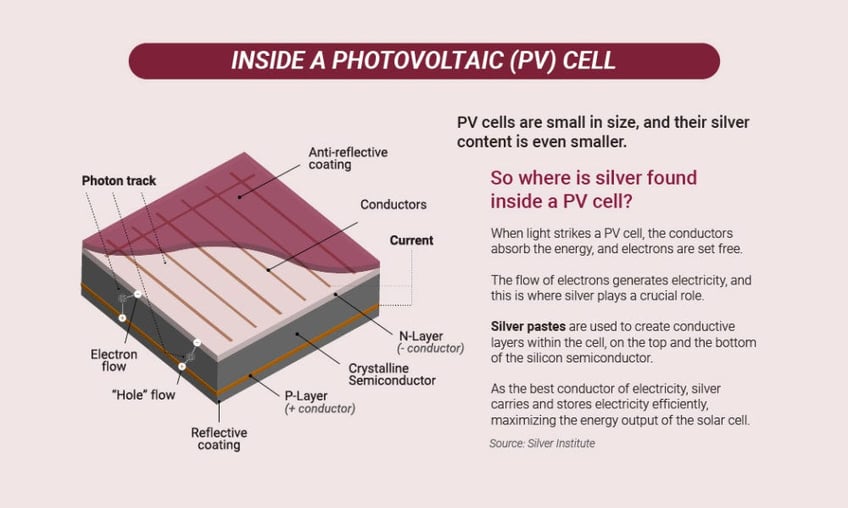

This piece will be about the portion of the supply-chain schematic above between Mining and installation. This is where Silver gets fabricated into Solar panels and is referred to commonly as the Value-added section of the chain or Value-chain.

The value-added parts of this supply chain (as in most chains) are the middle parts in CAPS below

Mining>REFINING>SOLAR PANEL CREATION> Panel installation

Here are all those sections broken out in more detail…

3- What is the Silver Value-Chain?

We can differentiate between Supply-Chain and Value-Chain this way:

The main difference between a value chain and a supply chain is that the supply chain deals with building the product and getting it to the consumer, while the value chain looks for ways to enhance the product's value as it moves along that supply chain.

Value chains are sufficiently complex enough to get their own focus. But it is helpful to understand that in general, as Bai reminded us, save for the assembly of panels, almost the whole supply chain in Silver is the refinement process. Value-Chains are that part of the supply chain that add value to the raw material to be made into a product. There can be services and other abstract logistics as well. But for our purposes in discussing Silver, refinement and final assembly are the Silver value-chain.

4- Sweet Spot Analysis

Refining>Powder>Paste >Solar Cell>Solar Panel

China seemingly dominates most of the value-added section of their domestic production value chain ( “vertical integration” applies here) with one exception.

For that one exception we shall see China has taken measures (for now) to make that part of the chain as reliably secure as possible through inter-dependency. We will come back to that exception in a bit.

The subtitle uses the word sweet-spot because the value-added section has the highest profits as a function of needing the most technological expertise. It is where human ingenuity does its best work and where the most money is made. Humans add the value here.

Their Solar value-chain dominance should dispel western illusions that China is lacking in high-end technology skills for production.

As we go backwards (travel upstream in the value-chain section) from finished product back to raw material we can get a better feel for several aspects of Silver use.

5- What Else the Value Chain Says

The value chain also tells a story about industrial progress in China. Simply put: whereas China manufacturing once was relegated to the non-value portions of many supply chains, we now see not only that they dominate some value added portions, but it reveals a timeline of their progress getting there.

By examining various points we can see the amount of metal used, the cost inputs, and the marketshare in that process2. We can also get an evolutionary view of how Chinese industry has grown into providing much if not all of the added value in the finished goods it now sells to the west.

Here is the value-added portion of that supply chain again

Refining>Powder>Paste >Solar Cell>Solar Panel

We will start on the right of this flow chart above and work our way left now.

6- SOLAR CELLS> SOLAR PANELS

Working backwards (upstream) we start at Solar Panels and Solar Cells. According to Bai, China accounts for a large part of this value-added piece.

China is the world's largest manufacturer of photovoltaic panels [Solar Panels] and modules [Cells], with a global market share of 70%; 90% of China's photovoltaic panels and module products are exported to European and American countries.

This is pretty straight forward. China makes the solar cells and subsequent panels that get shipped overseas. The main takeaway here is, China has all but absorbed this part of the chain into its industrial base.

7- PASTE>

Working upstream from there towards the Paste section, we see China’s presence in Paste manufacture is also massive...

Continues here UNLOCKED

Free Posts To Your Mailbox